Professional Zinc Plating Malaysia: Essential Insights for 2025

Understanding Zinc Plating: The Basics

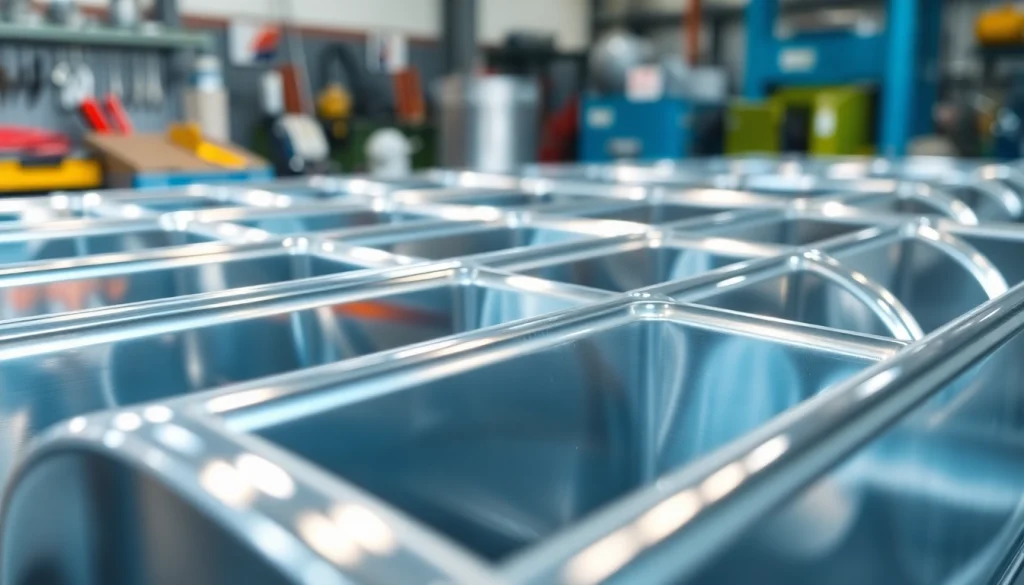

Zinc plating is an electrochemical process that applies a layer of zinc coating to steel and iron substrates. This technique is crucial for enhancing corrosion resistance and extends the lifespan of components used in various industries. As industries across Malaysia increasingly prioritize durability and aesthetics in their products, the demand for effective solutions like zinc plating malaysia has seen a significant rise. Understanding the fundamentals of zinc plating will help businesses make informed decisions regarding their manufacturing processes.

What is Zinc Plating?

Zinc plating, often referred to as zinc electroplating, involves immersing metal parts into an electrolyte solution that contains zinc salts. An electric current is then passed through the solution, causing zinc ions to deposit onto the surface of the metal parts, forming a protective layer. This process not only shields the underlying metal from rust and corrosion but can also enhance the component’s overall appearance.

The Importance of Zinc Plating in Various Industries

Zinc plating is widely recognized for its vital role across numerous sectors, including automotive, construction, and consumer goods. In the automotive industry, for example, zinc plating protects critical parts like chassis and bolts from severe environmental conditions, ensuring reliability and safety. Similarly, construction materials benefit from zinc’s protective qualities, leading to longer-lasting structures. Understanding these industry-specific applications helps stakeholders recognize the critical importance of zinc plating in maintaining product integrity.

How Zinc Plating Works: The Process Explained

The zinc plating process generally involves several key steps:

- Surface Preparation: The metal parts must be cleaned thoroughly to remove any contaminants, oils, or rust that could interfere with the adhesion of the zinc coating.

- Electrolytic Bath: Parts are submerged in a solution of zinc sulfate or zinc chloride, where they are subjected to an electric current that facilitates zinc deposition.

- Post-Treatment: After plating, parts may undergo additional treatments such as passivation to enhance corrosion resistance further.

Each step is critical in achieving a high-quality, durable coating.

Benefits of Zinc Plating in Malaysia

With a growing manufacturing base in Malaysia, industries are recognizing the numerous benefits that zinc plating offers. From protection against corrosion to aesthetic enhancements, zinc plating provides an advantageous solution for a range of applications.

Corrosion Resistance: Why It Matters

The primary purpose of zinc plating is to offer corrosion resistance. In a humid and tropical climate like Malaysia’s, where moisture can accelerate rusting, zinc serves as a sacrificial anode. This means that under corrosive conditions, the zinc layer corrodes instead of the underlying metal. The result is prolonged longevity of products, reducing maintenance costs significantly.

Cost-Effectiveness of Zinc Plating Services

Zinc plating is known for being one of the most cost-effective methods of protecting metal components. The relatively low material costs and straightforward application process translate into savings for manufacturers. Furthermore, by reducing corrosion-related failures, companies can achieve substantial savings over time, making zinc plating a practical choice for many businesses.

Improving Aesthetic Appeal with Zinc Finishes

Aside from functional benefits, zinc plating can enhance the visual appeal of components. Available in a range of finishes, from bright to matte, zinc can be tailored to meet specific aesthetic requirements. This versatility makes it particularly appealing for consumer products, where appearance is often as critical as function.

Choosing the Right Zinc Plating Service

Selecting a reputable zinc plating service is essential for ensuring quality and reliability. With several options available in Malaysia, it is vital to consider various factors to make an informed decision.

Key Factors to Consider When Selecting a Provider

When evaluating potential zinc plating services, consider the following:

- Experience: Look for companies with a proven track record in the industry and expertise in handling the specific materials and components you require.

- Quality Control: Reputable service providers implement stringent quality control measures throughout the plating process to ensure consistency and reliability.

- Compliance: Ensure the provider complies with international standards and regulations related to metal finishing.

Comparing Quality and Pricing of Zinc Plating Services in Malaysia

While cost is an important consideration, it shouldn’t be the sole factor. When comparing providers, assess the quality of their work through samples or case studies. A less expensive option may not always provide the same level of service or product quality as a slightly more costly alternative.

Reading Customer Reviews and Testimonials

Customer feedback is a valuable resource when selecting a zinc plating service. Look for testimonials or reviews that highlight aspects such as customer service, turnaround times, and overall satisfaction. Engaging with previous clients can provide insights into what you can expect from the service.

Common Challenges in Zinc Plating

While zinc plating is an effective solution, businesses may encounter various challenges throughout the process. Understanding these challenges can help mitigate risks and enhance outcomes.

Identifying and Avoiding Common Issues

Common issues in zinc plating include poor adhesion, uneven coating thickness, and contamination. These problems can arise from inadequate surface preparation or improper bath chemistry. By working with experienced professionals who adhere to best practices, businesses can avoid these pitfalls and ensure high-quality results.

Addressing Misconceptions About Zinc Plating

There are several misconceptions surrounding zinc plating, such as the belief that it is only suitable for certain applications. In reality, zinc plating can be effectively applied to various substrates and is beneficial across multiple industries.

Best Practices for Successful Zinc Plating

To achieve optimal results, consider the following best practices:

- Thorough Cleaning: Ensure all parts are meticulously cleaned before plating.

- Proper Bath Maintenance: Regularly monitor and maintain bath chemistry to ensure consistent quality.

- Quality Inspection: Conduct thorough inspections post-plating to verify coating quality and adhesion.

Future Trends in Zinc Plating Industry (2025 and Beyond)

As we look towards the future, the zinc plating industry is poised to evolve significantly. Key trends are shaping the landscape for zinc plating services in Malaysia.

Technological Advancements in Zinc Coating Techniques

Emerging technologies are driving innovation within the zinc plating sector. Techniques such as plasma electrolytic oxidation and the development of advanced zinc alloys are enabling stronger, more durable coatings. These advancements will likely lead to enhanced performance in critical applications.

Environmental Considerations in Zinc Plating

Increasingly, businesses are focused on sustainability practices. As a result, the zinc plating industry is exploring eco-friendly alternatives and methods to minimize environmental impact. Investment in cleaner technology and waste reduction strategies will be crucial in meeting future regulatory demands.

Market Predictions for Zinc Plating Services in Malaysia

The market for zinc plating services in Malaysia is expected to grow steadily as manufacturing expands. Industries such as automotive, construction, and electronics will drive demand, pushing service providers to enhance their offerings and adopt innovative technologies. Businesses that adapt to these trends will be well-positioned for success in the years to come.